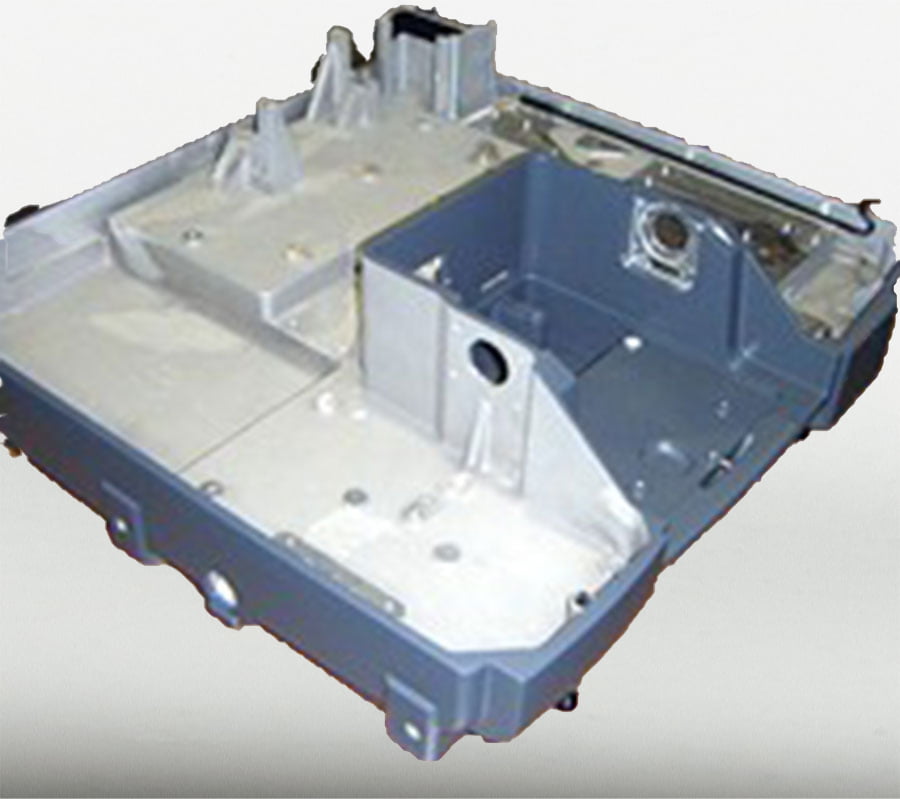

CNC & MACHINED ALUMINUM CASTINGS SPECIALISTS

Specializing in Precision CNC Machining of

Billet and Aluminum Castings for Medical,

Instrumentation, and Industrial Markets

Resolving Design and Production Challenges for Aluminum Castings

- Solve problems with existing casting design

- Convert weldments and assemblies to castings to yield cost reductions and performance gains

- Find the most efficient casting and machining process to minimize part cost

- Meet tight dimensional tolerances

- Source castings from qualified foundries

TMI is able to provide fast turn around on prototypes because of our relationships with foundries.

Partnering to Accelerate Your Product

Development Process